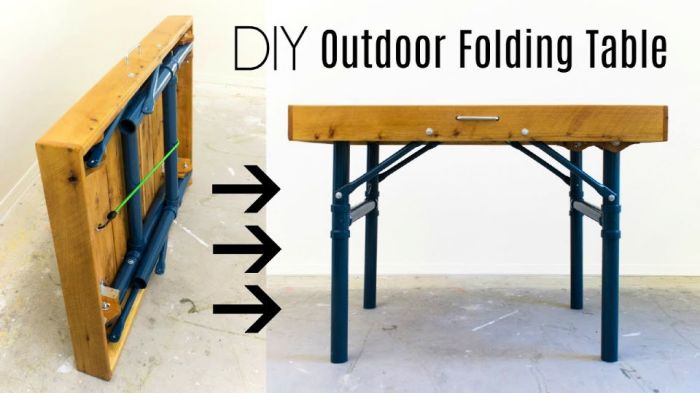

Folding DIY tables offer a practical and versatile solution for any space, from compact apartments to expansive backyards. These ingenious creations combine functionality with affordability, allowing you to craft custom tables that meet your specific needs and style preferences. Whether you’re looking to build a sturdy picnic table for outdoor gatherings, a stylish coffee table for your living room, or a functional workbench for your workshop, a folding DIY table provides a space-saving and adaptable solution.

This guide will delve into the world of folding DIY tables, exploring design considerations, construction techniques, and creative variations. From selecting the right materials and hinges to adding decorative touches and safety precautions, we’ll provide comprehensive s to help you create a folding table that’s both functional and aesthetically pleasing.

Folding DIY Tables: A Guide to Versatility and Affordability

Folding DIY tables offer a fantastic solution for those seeking space-saving, versatile, and budget-friendly furniture options. They can be easily stored away when not in use, making them perfect for small spaces or for those who need to quickly transform their environment. These tables are also highly customizable, allowing you to create pieces that perfectly match your style and needs.

Types of Folding DIY Tables

Folding DIY tables come in a variety of styles, each serving a unique purpose. Here are some common types:

- Picnic Tables: These sturdy tables are ideal for outdoor gatherings and can be easily folded for storage. They often feature a bench-style seating arrangement, making them perfect for family picnics or backyard barbecues.

- Coffee Tables: Folding coffee tables are great for small living rooms or apartments. They can be folded away when not in use, freeing up floor space. Some designs feature built-in storage compartments for added functionality.

- Workbenches: Folding workbenches are essential for DIY enthusiasts and craftspeople. They provide a stable work surface that can be easily folded away when not in use. These workbenches often feature built-in shelves or drawers for storing tools and materials.

Materials for Folding DIY Tables

Folding DIY tables can be made from a variety of materials, each offering unique advantages:

- Wood: A classic and durable material, wood is often used for folding tables. It is easy to work with and can be stained or painted to match any décor. Pine and plywood are popular choices for their affordability and ease of use. Hardwoods like oak and maple are more durable and offer a more luxurious look.

- Metal: Metal folding tables are known for their strength and durability. They are often used for outdoor furniture or for workbenches. Steel is a common choice for its strength and affordability. Aluminum is lighter and more resistant to corrosion, making it a good option for outdoor use.

- Plastic: Plastic folding tables are lightweight and easy to clean, making them perfect for indoor and outdoor use. They are also very affordable, making them a great option for temporary or occasional use.

Design Considerations

Designing a folding DIY table involves careful consideration of several factors to ensure functionality, durability, and aesthetic appeal. This section explores key aspects of design, including size, shape, weight, materials, and folding mechanisms.

Table Size and Shape

The size and shape of the table should be determined based on its intended use and the available space. For example, a small folding table might be ideal for a balcony or patio, while a larger table might be suitable for dining or work. Common shapes include rectangular, square, round, and oval. Consider the number of people who will be using the table and the activities that will be performed on it.

Table Weight

The weight of the table is an important consideration, especially if it will be moved frequently. A lightweight table is easier to transport and store, but it may be less sturdy. Consider the materials used and the design to achieve a balance between weight and durability.

Material Selection

The choice of materials for the table top, legs, and frame depends on the intended use and the desired level of durability.

- For tabletops, popular choices include plywood, MDF, solid wood, or even laminate. Plywood offers a balance of strength and affordability, while solid wood provides a more elegant and durable option. MDF is a cost-effective choice but can be less resistant to moisture. Laminate is a durable and easy-to-clean option, but it may not be as aesthetically pleasing as wood.

- For table legs and frames, consider using sturdy wood, metal, or a combination of both. Hardwood like oak or maple is strong and durable, while softwood like pine or fir is more affordable but may be less robust. Metal legs, such as steel or aluminum, offer strength and durability, and can be lightweight.

Folding Mechanisms

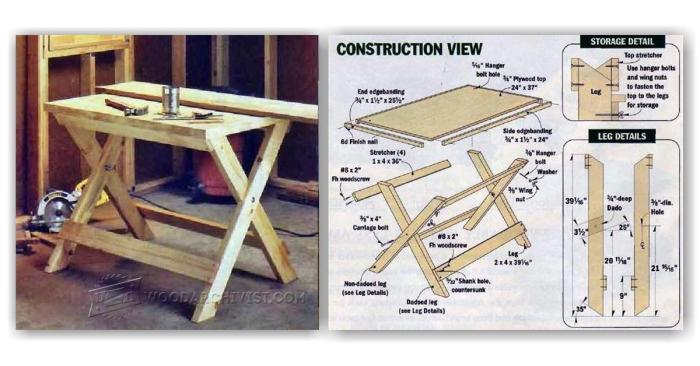

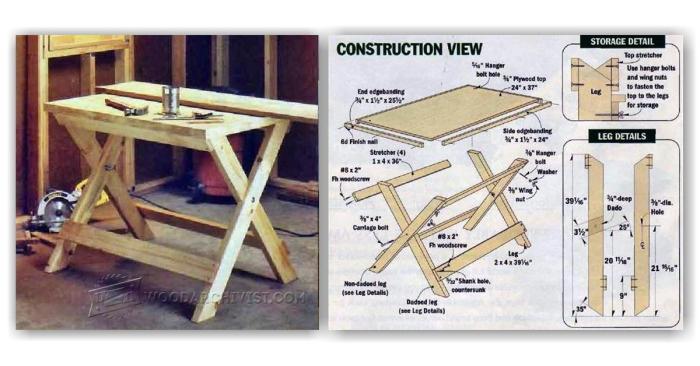

Folding tables utilize various mechanisms to facilitate easy storage and transport.

- Hinges: These are the most common folding mechanism. They allow the table top to fold in half or into multiple sections. Hinges can be made from metal, wood, or plastic, and come in various styles, such as piano hinges, butterfly hinges, and continuous hinges. Piano hinges are robust and ideal for heavy-duty tables, while butterfly hinges are more compact and suitable for lighter tables. Continuous hinges offer a smooth folding action and are often used in tables with multiple folding sections.

- Locking Mechanisms: These are crucial for ensuring the table is secure when folded and unfolded. Locking mechanisms can be simple latches, spring-loaded catches, or more complex systems. A secure locking mechanism is essential for preventing the table from accidentally collapsing when in use.

- Folding Legs: Folding legs are often used in conjunction with hinges to create a compact folding table. These legs can be made from metal, wood, or plastic, and can be designed to fold in various ways, such as X-shaped, Z-shaped, or telescoping.

Construction Process

The construction process for a folding DIY table involves a series of steps that require careful planning and execution. From cutting the wood to assembling the components, each step is crucial to ensure the table’s stability, functionality, and durability.

Tools and Equipment

Before embarking on the construction process, gather the necessary tools and equipment to ensure a smooth and efficient workflow.

- Measuring Tape: Accurate measurements are essential for precise cutting and assembly. Choose a tape measure with clear markings and a sturdy body.

- Saw: A saw, such as a circular saw or a jigsaw, is required for cutting the wood to size. Ensure the saw is sharp and in good working condition for clean cuts.

- Drill: A drill is needed for creating pilot holes for screws and assembling the table components. Choose a drill with a variety of drill bits to accommodate different screw sizes.

- Screwdriver: A screwdriver is necessary for driving screws into the wood. Select a screwdriver with a comfortable grip and a magnetic tip for easier screw insertion.

- Clamps: Clamps are used to hold the wood pieces together during assembly, ensuring accurate alignment and preventing movement. Choose clamps with a strong grip and adjustable jaws.

- Sandpaper: Sandpaper is used to smooth out any rough edges or imperfections on the wood surfaces, creating a finished look. Choose a variety of sandpaper grits for different levels of sanding.

- Safety Glasses: Safety glasses are essential to protect your eyes from flying debris during cutting and sanding. Choose safety glasses with a snug fit and clear lenses.

- Work Gloves: Work gloves provide protection for your hands from splinters and rough surfaces during handling and assembly. Choose gloves with a good grip and durable material.

Cutting the Wood

Cutting the wood to the desired dimensions is the first step in constructing a folding DIY table.

- Measure Carefully: Before making any cuts, double-check the measurements to ensure accuracy. Any errors in cutting can lead to misaligned components and a wobbly table.

- Use a Guide: For precise cuts, use a guide such as a straight edge or a miter saw. This will help ensure that the cuts are straight and at the correct angles.

- Make Smooth Cuts: When using a saw, make smooth, controlled cuts to avoid splintering or uneven edges. This will ensure that the table components fit together properly.

- Safety First: Always wear safety glasses and work gloves when cutting wood. Be aware of your surroundings and avoid distractions to prevent accidents.

Assembling the Table

Assembling the table components involves joining the cut pieces of wood to form the table frame and top.

- Pre-Drill Holes: Before driving screws into the wood, pre-drill pilot holes to prevent splitting. The pilot holes should be slightly smaller than the diameter of the screws.

- Use Clamps: Use clamps to hold the wood pieces together during assembly, ensuring accurate alignment and preventing movement. This will help create a sturdy and stable table.

- Drive Screws Securely: Drive the screws securely into the wood, but avoid overtightening, which can cause damage to the wood. Use a screwdriver with a magnetic tip for easier screw insertion.

- Check for Alignment: Regularly check the alignment of the table components during assembly to ensure that the table is square and level. This will prevent any unevenness or wobbles in the finished product.

Finishing the Table, Folding diy table

Once the table is assembled, the final step is to finish the wood surfaces to protect them and enhance their appearance.

- Sand the Surfaces: Sand the wood surfaces with sandpaper to remove any rough edges or imperfections. Start with a coarse grit sandpaper and gradually move to a finer grit for a smooth finish.

- Apply Stain or Paint: Apply a stain or paint to the wood surfaces to protect them from moisture and enhance their appearance. Choose a stain or paint that complements the table’s design and style.

- Apply a Protective Finish: After the stain or paint has dried, apply a protective finish, such as a varnish or polyurethane, to seal the wood surfaces and provide a durable layer of protection.

Folding Mechanism

The folding mechanism is the heart of a DIY folding table, dictating its functionality and durability. Choosing the right mechanism depends on your design goals, desired functionality, and your skill level. Let’s explore some popular options and delve into creating a sturdy and reliable folding mechanism.

Types of Folding Mechanisms

There are several types of folding mechanisms commonly used in DIY tables. Each has its advantages and disadvantages, making it crucial to choose the one that best suits your project.

- Butterfly Hinges: Butterfly hinges are a popular choice for folding tabletops. They allow the tabletop to fold in half, creating a compact storage solution. These hinges are relatively simple to install and can be found at most hardware stores. Butterfly hinges are ideal for smaller tables where a compact folding design is desired.

- Drop-Leaf Mechanisms: Drop-leaf mechanisms are often used in dining tables. They allow one or both ends of the table to fold down, creating a smaller table when needed. Drop-leaf mechanisms can be more complex to install than butterfly hinges, but they offer greater flexibility in terms of table size.

- Scissor Mechanisms: Scissor mechanisms are used for folding tables that need to be compact and portable. They utilize a system of interlocking arms that fold the table into a flat, compact package. Scissor mechanisms are often used in camping tables and other portable furniture.

Creating a Sturdy Folding Mechanism

The strength and reliability of a folding mechanism depend on several factors, including the materials used, the design, and the quality of construction.

- Material Selection: Choosing the right materials is crucial for a sturdy and reliable folding mechanism. Steel hinges are strong and durable, while wooden hinges can add a rustic touch. For larger tables, consider using heavy-duty hinges designed for high-load applications.

- Reinforcement: For added strength and stability, consider reinforcing the folding mechanism with brackets or plates. These reinforcements can help to distribute the load evenly and prevent the mechanism from bending or breaking under stress.

- Proper Installation: The proper installation of the folding mechanism is essential for its smooth and secure operation. Ensure that all screws and bolts are securely fastened and that the mechanism is properly aligned.

Testing the Folding Mechanism

Once the folding mechanism is installed, it’s crucial to test its functionality thoroughly. This involves repeatedly folding and unfolding the table to ensure it operates smoothly and securely.

- Smooth Operation: The folding mechanism should move smoothly and effortlessly without any binding or jamming. If you encounter any resistance, check for any misalignment or obstruction.

- Secure Locking: The folding mechanism should lock securely in both the open and closed positions. This prevents the table from accidentally collapsing or unfolding when in use.

- Load Testing: To assess the strength of the folding mechanism, apply a load to the table and test its stability. This can involve placing heavy objects on the table or simulating the weight of people sitting on it.

Finishing Touches: Folding Diy Table

The final step in your DIY table project is applying finishing touches. This stage is crucial as it enhances the table’s appearance, protects the wood, and adds durability.

Sanding and Finishing

Sanding and finishing the table surface is essential for achieving a smooth and durable finish. It involves removing any imperfections, such as rough edges, scratches, or saw marks, and creating a uniform surface for the paint, stain, or varnish to adhere to.

- Start by sanding the table with progressively finer grit sandpaper. This helps to smooth out the surface and remove any blemishes.

- After sanding, clean the table surface thoroughly to remove any dust or debris.

- Apply a primer to the table surface before applying the final finish. This helps to create a uniform base for the paint, stain, or varnish.

- Apply the chosen finish in thin, even coats, allowing each coat to dry completely before applying the next.

- Finish with a sealant to protect the table surface from scratches, spills, and other damage.

Applying Paint, Stain, or Varnish

There are various types of paint, stain, or varnish that can be used to finish a table. Each option offers different aesthetic and protective qualities.

- Paint: Paint is a versatile option that offers a wide range of colors and finishes. It can be used to create a solid color, a distressed look, or even a metallic effect.

- Stain: Stain is a penetrating finish that enhances the wood’s natural grain pattern and color. It comes in various shades and tones, allowing you to create a natural or dramatic look.

- Varnish: Varnish is a clear finish that protects the wood surface from scratches, spills, and moisture. It can be used to create a glossy, satin, or matte finish.

Adding Decorative Elements

Adding decorative elements can enhance the table’s appearance and make it unique. Here are some ideas:

- Stencils: Stencils can be used to create patterns, designs, or lettering on the table surface.

- Carvings: Carvings can add intricate details and depth to the table’s design.

- Inlays: Inlays involve inserting different materials, such as wood, metal, or stone, into the table surface to create patterns or designs.

With a little creativity and effort, you can build a folding DIY table that enhances your living space and reflects your personal style. From choosing the perfect design to adding unique finishing touches, the process is rewarding and empowering. Embrace the joy of DIY and create a folding table that becomes a cherished piece of furniture, bringing practicality and beauty to your home or workspace.

Folding DIY tables are great for saving space, but sometimes you need a standing option. If you’re looking to add a standing desk to your setup without breaking the bank, consider a DIY standing desk converter. You can find plenty of tutorials online for building your own, like this one for a DIY standing desk converter. Once you have your standing desk converter, you can use it with your folding table to create a versatile workspace that meets your needs.